TEMPERATURE INDICATORS

• Blood Temp 10

• ColdMark

• WarmMark

• WarmMark Duo

• WarmMark Long Run

Temperature Indicators & Recorders

Temperature monitors, indicators and recorders introduce accountability measures into the shipping and handling stages of the temperature sensitive cold chain. By providing prominent visual notification to shipping personnel of the presence of monitoring equipment, indicators and recorders encourage proper handling and transport of temperature sensitive products. In the event that a temperature excursion occurs, indicators and recorders give you the data needed to improve the integrity of the cold chain.

Temperature monitoring and measuring devices play a vital role in identifying temperature-related events, and empower you to take meaningful action to reduce the likelihood of product damage.

Blood Temp 10

Simple quality assurance for blood temperature during transportation and storage.

Easy to use: Simple push button indicator that requires no special conditioning prior to use and is cost-effective.

Quality assurance: Maintain quality control in blood transportation and storage with real-time data to make quick, safe decision for peace of mind.

Ensure compliance: Irreversible proof of meeting AABB standards and the FDA’s CFR 600.15(a) for monitoring temperature of whole blood during transportation and storage. FDA 510(k) clearance.

ColdMark

ColdMark, a single-use descending temperature indicator, is designed to help shippers identify and correct gaps in their cold chain. The ColdMark turns from clear to violet when the temperature goes below a predetermined threshold.

Available Temperatures

-3°C / 26°F

0°C / 32°F

2°C / 36°F

5°C / 41°F

10°C / 50°F

WarmMark

WarmMark is a single-use, ascending time-temperature indicator which alerts users of exposure to unacceptable temperature conditions. The WarmMark is available in the following temperature sensitivities:

-18°C / 0°F

0°C / 32°F

5°C / 41°F

8°C / 46°F

10°C / 50°F

20°C / 68°F

25°C / 77°F

30°C / 86°F

37°C / 99°F

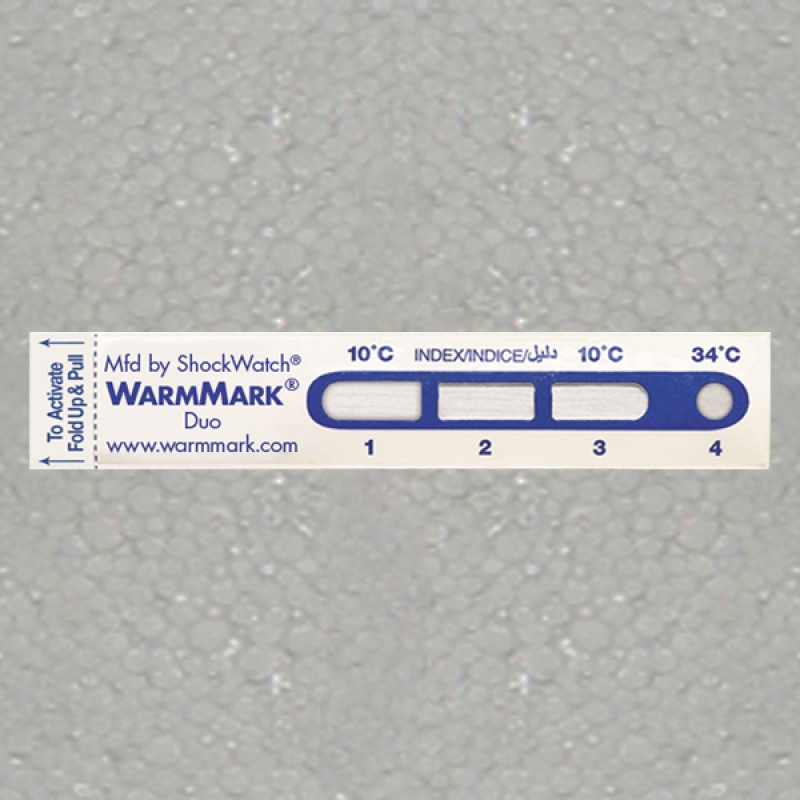

WarmMark Duo

The ShockWatch WarmMark® Duo is a cost-effective, disposable temperature indicator that monitors temperatures during shipping and storage, indicating whether goods have been subjected to unacceptable conditions. These reliable temperature indicators provide visual evidence of exposure to unacceptable temperature levels, allowing you to determine if product quality has been compromised. It is ideal for products with a known temperature stability curve and expiration characteristics at certain time and temperature combinations.

WarmMark Duo Indicates the duration of temperature exposure at two different activation temperature levels. If the windows in the WarmMark Duo indicator stay white, there’s no problem. But if the temperature climbs beyond two specific thresholds, a red color moves through the windows of the indicator with the passage of time. If the temperature returns to below the threshold, the color stops moving. In this way, handlers and shippers can know how long the product was exposed above the threshold temperature.

• Monitor for the length of time above 10°C and for brief excursions above 34°C

• Know if a product has been exposed past a threshold and check for high temperature spikes.

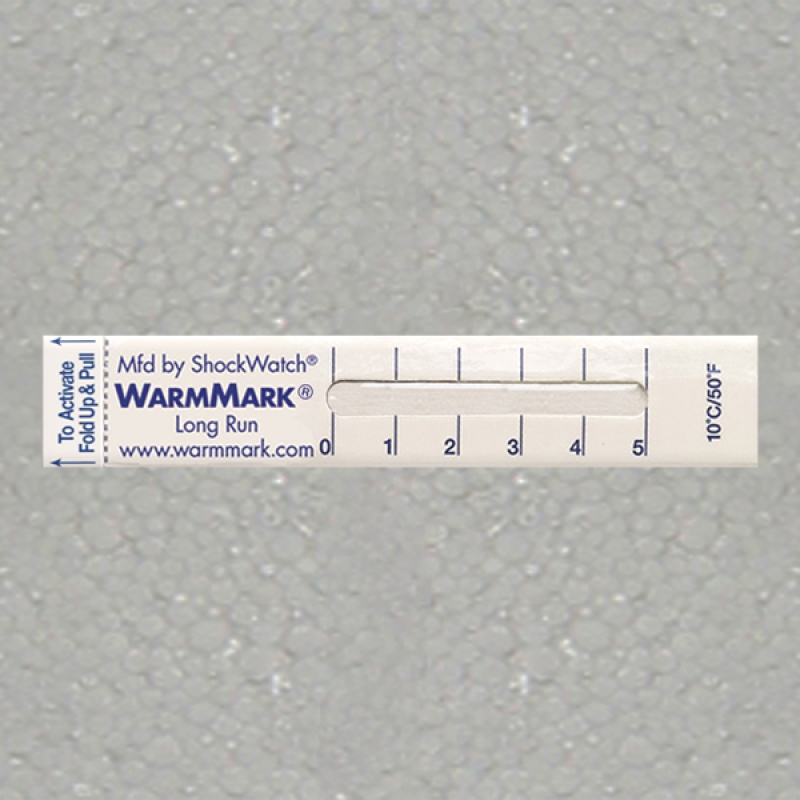

WarmMarkLongRun

The ShockWatch WarmMark® Long Run is a cost-effective, disposable temperature indicator that monitors temperatures during transport and storage, indicating whether goods have been subjected to unacceptable conditions. Affixed directly to your products or their packaging, these reliable temperature indicators provide visual evidence of exposure to unacceptable temperature levels, allowing you to determine if product quality has been compromised. Use of the WarmMark Long Run can have a positive effect on your bottom line because it indicates a product’s long-term exposure to temperature excursions.

If the window of the WarmMark® Long Run indicator stays white, there’s no problem. But if the temperature climbs beyond a specific threshold, a red dye moves through the windows of the indicator with the passage of time. If the temperature returns to below the threshold, the dye stops its progression. In this way, handlers and shippers can know how long the product was exposed above the threshold temperature.